A recreational venue situated in Louisiana’s capital city, this establishment provides a space for roller skating activities. It is located within the Baton Rouge metropolitan area and offers roller skating as its primary form of entertainment, often hosting events and open skating sessions for the local community.

Such establishments contribute to community well-being by providing accessible recreational opportunities for individuals of all ages. They foster physical activity, social interaction, and a sense of community belonging. Historically, roller skating rinks have served as important social hubs, offering a safe and enjoyable environment for families and individuals to gather and engage in physical activity.

The following sections will explore related aspects, including event schedules, safety guidelines, and community impact, offering a detailed overview of the venue’s offerings and its role within the local recreational landscape.

Tips for Enhancing the Roller Skating Experience

The following recommendations are designed to optimize safety, enjoyment, and skill development for participants at roller skating venues.

Tip 1: Protective Gear is Essential: Always wear appropriate protective gear, including a helmet, wrist guards, elbow pads, and knee pads. This significantly reduces the risk of injury in the event of a fall.

Tip 2: Warm-Up Prior to Skating: Engage in light stretching and warm-up exercises before beginning to skate. This prepares muscles and joints, minimizing the likelihood of strains or sprains.

Tip 3: Maintain a Stable Stance: Practice maintaining a low center of gravity with knees bent. This stance enhances balance and control, particularly at higher speeds or during maneuvers.

Tip 4: Utilize Available Resources: Take advantage of any available lessons or instructional sessions offered at the facility. Professional guidance can accelerate skill acquisition and improve technique.

Tip 5: Be Aware of Surroundings: Pay close attention to the movements and positions of other skaters to avoid collisions. Maintain a safe distance and skate predictably.

Tip 6: Skate Within Skill Level: Avoid attempting advanced maneuvers before mastering fundamental skills. Gradual progression is key to safe and effective skill development.

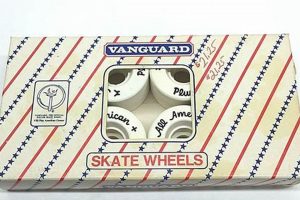

Tip 7: Check Equipment Regularly: Inspect skates for any loose wheels, worn bearings, or other signs of damage. Proper maintenance ensures optimal performance and safety.

Adhering to these guidelines will contribute to a safer and more rewarding experience at any roller skating facility, promoting both individual well-being and a positive skating environment for all.

The subsequent sections will delve into specific programs and events offered, further illustrating opportunities for skill enhancement and community engagement.

1. Roller Skating

Roller skating serves as the core activity and defining feature of this recreational establishment. Its relevance lies in providing a physical, social, and engaging experience for individuals of all ages. Further exploration reveals various facets that contribute to the overall roller skating experience offered at the venue.

- Open Skate Sessions

Open skate sessions represent regularly scheduled periods during which the facility is open to the public for recreational roller skating. These sessions typically cater to a wide range of skill levels and ages, offering a non-structured environment for individuals to enjoy skating. Examples include weekend afternoon skates or evening sessions. Implications involve providing consistent opportunities for recreational activity and social interaction within the community.

- Themed Skate Nights

Themed skate nights involve organizing skating sessions around specific themes, such as disco nights, holiday celebrations, or decade-themed events. These events often incorporate themed music, decorations, and costumes to enhance the experience. Implications include attracting diverse audiences and creating a more engaging and festive atmosphere.

- Private Parties and Events

The venue offers the option to host private parties and events, such as birthday celebrations, corporate gatherings, or school outings. This typically involves reserving the facility for a specific time period and providing customized services, such as catering or event planning. Implications include generating revenue and providing a unique venue for special occasions.

- Roller Skating Lessons and Instruction

Roller skating lessons and instruction provide structured learning opportunities for individuals to develop their skating skills. These lessons may be offered to beginners, intermediate skaters, or advanced skaters, covering topics such as basic skating techniques, advanced maneuvers, and safety procedures. Implications include promoting skill development, increasing confidence, and enhancing safety awareness among skaters.

These facets of roller skating directly contribute to the overall experience at the skating facility. By offering a diverse range of roller skating activities, the venue aims to cater to a wide range of interests and skill levels, ultimately fostering a vibrant and engaging recreational environment.

2. Family Entertainment

Family entertainment constitutes a significant aspect of recreational venues such as roller skating rinks. The ability to provide enjoyable activities for multiple age groups and family units enhances the value and appeal of the establishment. Analyzing its specific components reveals how this function is fulfilled.

- All-Ages Accessibility

This refers to the capacity of the facility to accommodate individuals across a broad spectrum of ages, from young children to adults. For instance, the provision of smaller-sized skates, skating aids for beginners, and designated areas for novice skaters ensures that even young children or those new to the activity can participate safely and comfortably. The implication is an increased potential customer base and a broader appeal to family units.

- Variety of Activities

In addition to roller skating, the availability of supplementary activities such as arcade games, concession stands, and music playlists caters to diverse interests and preferences within a family. For example, while some family members may be actively skating, others can engage in arcade games or enjoy refreshments. The implication is reduced boredom and increased engagement, leading to longer visits and higher customer satisfaction.

- Safe Environment

The provision of a secure and supervised environment is essential for family entertainment. This includes measures such as clearly defined rules of conduct, adequate staffing to monitor the skating floor, and readily available first aid services. For example, trained staff members can quickly address any accidents or enforce rules to prevent reckless behavior. The implication is increased parental peace of mind and a greater willingness to allow children to participate.

- Affordable Pricing

Competitive pricing structures and family-oriented packages contribute to the affordability and accessibility of the venue. For instance, offering discounted rates for family groups or providing bundled packages that include skating admission, skate rentals, and arcade game credits can make the experience more financially accessible. The implication is increased patronage and a wider reach within the community.

These components collectively contribute to the designation of such recreational venues as family-friendly destinations. By catering to a diverse range of ages, interests, and financial constraints, these establishments aim to create a welcoming and enjoyable environment for family units to engage in shared recreational experiences.

3. Community Events

Community events represent a critical element in the operational framework of recreational facilities, fostering social interaction and enhancing the venue’s integration within the local area. These events, organized by or hosted at such establishments, serve to broaden their appeal and solidify their role as communal hubs.

- Fundraisers and Charity Skates

These events involve partnerships with local charities or organizations to raise funds for specific causes. For instance, a portion of the admission fees or skate rental proceeds during a designated event may be donated to a local food bank or animal shelter. The implications include generating goodwill, supporting community initiatives, and attracting individuals motivated by philanthropic purposes.

- School and Youth Group Outings

Facilitating organized outings for local schools, youth groups, and extracurricular organizations provides a structured recreational opportunity for young people. This may involve discounted rates, reserved time slots, and tailored activities to suit the specific needs of the group. The implications include fostering physical activity among youth, providing a safe and supervised environment, and establishing relationships with local educational institutions.

- Holiday-Themed Events

Organizing skating events around specific holidays, such as Halloween, Christmas, or Valentine’s Day, enhances the festive atmosphere and provides themed entertainment. These events may include costume contests, holiday-themed music, and special decorations. The implications include attracting families and individuals seeking seasonal entertainment and creating a memorable and engaging experience.

- Adult Skate Nights

Designating specific evenings for adult-only skating sessions caters to a demographic seeking social interaction and physical activity in a child-free environment. These events may feature different music genres, drink specials, and a more relaxed atmosphere. The implications include broadening the customer base, providing a space for adult recreation, and generating revenue during traditionally slower periods.

These community-oriented events serve to position establishments such as Skate Galaxy in Baton Rouge as valuable resources within the local landscape. By actively engaging with community organizations and hosting diverse events, these venues contribute to social cohesion, promote recreational opportunities, and solidify their presence as integral components of the community fabric.

4. Recreational Fitness

Recreational fitness, encompassing physical activities undertaken for enjoyment and health benefits, forms a crucial aspect of the services offered by establishments such as roller skating venues. The integration of fitness opportunities within a recreational setting enhances the appeal and value of these venues, contributing to the overall well-being of their patrons. The subsequent analysis outlines key facets of this relationship.

- Cardiovascular Exercise

Roller skating provides a sustained aerobic workout that elevates heart rate and improves cardiovascular health. Consistent skating sessions can contribute to improved endurance, reduced blood pressure, and a lower risk of heart disease. At a venue like Skate Galaxy in Baton Rouge, scheduled open skate sessions and themed nights offer opportunities for patrons to engage in cardiovascular exercise while enjoying a social and entertaining atmosphere. Regular attendance at these sessions contributes to increased physical activity levels among the local population.

- Muscular Strength and Endurance

Roller skating engages multiple muscle groups, including the legs, core, and arms, promoting both muscular strength and endurance. Maintaining balance and propelling oneself forward requires constant muscle activation, leading to improved muscle tone and stamina. Skate Galaxy, through its lesson programs and open skating events, provides a setting for individuals to develop these physical attributes. Participation in these activities can lead to increased strength and endurance over time.

- Balance and Coordination

Roller skating inherently demands balance and coordination, requiring skaters to maintain equilibrium while moving across a smooth surface. Regular practice improves these skills, enhancing overall motor control and reducing the risk of falls. Skate Galaxy’s skating surface and available training programs facilitate the development of these skills. Improved balance and coordination can have positive implications for individuals in other aspects of their lives, such as sports and daily activities.

- Low-Impact Exercise

Compared to high-impact activities like running or jumping, roller skating offers a relatively low-impact form of exercise, reducing the stress on joints and minimizing the risk of injury. This makes it a suitable option for individuals of varying ages and fitness levels, including those with joint pain or other physical limitations. Skate Galaxy provides a space for individuals to engage in physical activity without placing undue stress on their bodies. This accessibility broadens the appeal of the venue and promotes inclusivity within the community.

The integration of recreational fitness into the activities offered by roller skating venues such as Skate Galaxy underscores their contribution to community health and well-being. By providing accessible opportunities for cardiovascular exercise, muscular development, balance improvement, and low-impact activity, these establishments play a role in promoting a healthier and more active lifestyle for individuals of all ages and abilities.

5. Youth Activities

The provision of structured youth activities constitutes a significant operational component for establishments such as the roller skating venue in Baton Rouge. These activities, designed specifically for younger demographics, directly influence the venue’s appeal, community engagement, and overall success. A direct causal relationship exists: the presence and quality of youth activities influence attendance rates among families and younger individuals.

Youth activities serve multiple purposes, extending beyond mere recreation. They provide structured opportunities for physical activity, skill development (e.g., roller skating lessons), and social interaction within a supervised environment. Consider, for example, organized birthday parties, which not only generate revenue but also introduce new children and families to the facility. Similarly, after-school skating programs can provide a safe and engaging alternative to unsupervised activities, fostering positive community relationships. The absence of such programming would likely diminish the venue’s perceived value and relevance within the community.

Understanding the practical significance of youth activities allows the management of Skate Galaxy to strategically allocate resources and tailor programs to meet the evolving needs of the local youth population. This includes offering diverse program options, ensuring adequate staffing and supervision, and maintaining a safe and welcoming environment. By prioritizing youth activities, the venue can establish itself as a valuable community asset, fostering physical activity, social development, and a sense of belonging among young people.

6. Location Accessibility

Location accessibility represents a critical determinant of the patronage and success of recreational venues such as Skate Galaxy in Baton Rouge. Its influence stems from the direct impact that proximity, transportation options, and ease of navigation exert on the public’s ability to access and utilize the facility.

- Proximity to Residential Areas

The distance between Skate Galaxy and densely populated residential areas significantly influences its customer base. A location within close proximity to neighborhoods reduces travel time and transportation costs, thereby increasing the likelihood of spontaneous visits and regular patronage. For example, a location situated near established subdivisions or apartment complexes within Baton Rouge would likely experience higher foot traffic compared to a more remote location. The implication is a direct correlation between geographical accessibility and revenue generation.

- Availability of Public Transportation

The presence of readily available public transportation options, such as bus routes or shuttle services, expands the accessibility of Skate Galaxy to individuals who may not have access to private vehicles. A location situated along a major bus line or near a transit hub would benefit from increased accessibility for students, families with limited transportation resources, and elderly individuals. The implication is an expanded potential customer base beyond those with personal vehicle access.

- Road Network and Traffic Conditions

The ease with which individuals can reach Skate Galaxy via major roadways and arterial streets is a key consideration. A location situated near easily navigable roads with minimal traffic congestion ensures a smooth and efficient travel experience for patrons. Conversely, a location burdened by heavy traffic or difficult-to-access roads may deter potential visitors. The implication is that accessible roadways directly influence the perceived convenience and attractiveness of the venue.

- Parking Availability and Cost

Adequate and affordable parking facilities are essential for attracting customers who choose to drive to Skate Galaxy. Sufficient parking spaces ensure that patrons can easily find parking upon arrival, while reasonable parking fees prevent financial barriers to entry. A lack of parking or exorbitant parking costs may dissuade potential visitors from choosing the venue. The implication is that accessible and affordable parking directly contributes to the overall customer experience and influences patronage rates.

These facets of location accessibility collectively determine the ease with which individuals can access and utilize Skate Galaxy in Baton Rouge. A strategically chosen location, characterized by proximity to residential areas, availability of public transportation, navigable road networks, and adequate parking facilities, maximizes the venue’s potential for success and contributes to its role as a valuable community asset.

Frequently Asked Questions Regarding Skate Galaxy, Baton Rouge, Louisiana

The following section addresses common inquiries regarding the operation and features of the roller skating venue located in Baton Rouge, Louisiana. The information provided aims to offer clarity and assist potential patrons in making informed decisions.

Question 1: What are the standard operating hours for Skate Galaxy in Baton Rouge?

The operating hours vary depending on the day of the week and scheduled events. It is recommended to consult the official Skate Galaxy website or contact the venue directly for the most current schedule information.

Question 2: Does Skate Galaxy offer roller skate rentals, or is it necessary to bring personal skates?

Roller skate rentals are available on-site in a range of sizes to accommodate different age groups and foot sizes. Personal skates are permitted, provided they meet established safety standards. Management reserves the right to inspect and approve personal skates for safe usage.

Question 3: Are there specific age restrictions or supervision requirements for children at Skate Galaxy?

While Skate Galaxy aims to provide a family-friendly environment, specific age restrictions or supervision requirements may apply, particularly during certain events or evening hours. Parental discretion is advised, and adherence to posted signage regarding age restrictions is expected.

Question 4: What types of payment methods are accepted at Skate Galaxy?

Accepted payment methods typically include cash and major credit cards. Debit card acceptance may vary. Contact the venue directly to confirm current payment policies.

Question 5: Does Skate Galaxy offer group rates or private party bookings?

Group rates and private party bookings are available. Contact the Skate Galaxy management team to discuss specific requirements, pricing, and available dates.

Question 6: What safety measures are in place at Skate Galaxy to ensure a safe skating environment?

Skate Galaxy implements several safety measures, including rink monitoring by trained staff, clearly posted rules and regulations, and readily available first aid equipment. Patrons are encouraged to wear appropriate safety gear, such as helmets and wrist guards, to minimize the risk of injury.

In summary, Skate Galaxy offers a range of services and amenities. It is recommended to confirm details regarding operating hours, payment methods, and safety regulations prior to visiting.

The subsequent sections will delve into related aspects, including event schedules, safety guidelines, and community impact.

Conclusion

This exploration of Skate Galaxy, Baton Rouge, Louisiana, has illuminated key aspects of its role as a recreational venue. The analysis encompassed its core offering of roller skating, its emphasis on family entertainment, its engagement in community events, its contribution to recreational fitness, its programming for youth activities, and the influence of its location accessibility.

The future success of Skate Galaxy in Baton Rouge hinges upon its continued ability to adapt to evolving community needs and preferences. Sustained engagement with the local population, a commitment to safety, and the provision of diverse recreational opportunities will be crucial for its long-term viability and its continued role as a community asset.