The delivery of comestibles via unconventional means presents a novel approach to food distribution. One example of this involves the use of wheeled platforms, potentially motorized, to transport meals or ingredients to consumers or designated locations. This method provides mobility and accessibility for vendors and convenience for recipients.

The advantage of such a system lies in its potential to bypass traditional retail locations, offering a more direct route from preparation to consumption. This can reduce overhead costs and enhance speed of service, particularly in densely populated areas or at events. Historically, similar concepts have been explored using carts and mobile food vendors, but advancements in technology allow for more sophisticated and efficient implementation.

The subsequent sections will delve into specific aspects of this evolving sector, examining operational considerations, regulatory landscapes, and potential impacts on existing food industry models. Further discussion will address logistical challenges and explore innovative applications within diverse culinary contexts.

Operational Considerations for Mobile Food Platforms

Optimizing the efficiency and safety of transporting and delivering food via mobile platforms requires careful planning and adherence to best practices.

Tip 1: Route Optimization: Employ GPS tracking and route planning software to identify the most efficient paths. Minimize travel time and fuel consumption by considering traffic patterns and delivery schedules.

Tip 2: Temperature Control: Maintain food safety by utilizing insulated containers and temperature monitoring devices. Adhere to established guidelines for holding temperatures of both hot and cold food items.

Tip 3: Equipment Maintenance: Implement a regular maintenance schedule for all motorized platforms, ensuring proper function of brakes, tires, and other critical components. Preventive maintenance reduces the risk of breakdowns and accidents.

Tip 4: Regulatory Compliance: Ensure full compliance with local health and safety regulations regarding food handling, storage, and transportation. Obtain all necessary permits and licenses for operating a mobile food platform.

Tip 5: Secure Packaging: Utilize packaging that prevents spills and maintains food quality during transit. Consider using tamper-evident seals for added security and customer reassurance.

Tip 6: Staff Training: Provide comprehensive training to personnel on safe driving practices, food handling procedures, and customer service protocols. Emphasize the importance of hygiene and food safety.

Tip 7: Weather Preparedness: Develop contingency plans for inclement weather conditions, such as rain, snow, or extreme temperatures. This may involve adjusting routes, modifying delivery schedules, or temporarily suspending operations.

These guidelines aim to enhance the reliability, safety, and efficiency of mobile food platforms, contributing to a positive customer experience and maintaining regulatory compliance.

The concluding sections will further analyze the long-term viability and societal implications of this evolving mode of food distribution.

1. Regulation Compliance

Adherence to established regulatory frameworks is paramount for the legal and safe operation of any mobile food distribution system. These compliance measures ensure public health, consumer safety, and fair business practices within the sector.

- Food Safety Standards

Food safety standards, mandated by local and national health authorities, dictate the conditions under which food must be stored, prepared, and transported. Non-compliance can result in fines, temporary suspension of operations, or permanent revocation of permits. For instance, mobile food platforms must demonstrate appropriate temperature controls and sanitation procedures to prevent foodborne illnesses.

- Vehicle and Equipment Permits

Mobile food platforms often require specific permits related to vehicle operation and equipment usage. These permits ensure that the platforms meet safety standards for roadworthiness and that any onboard cooking or refrigeration equipment is properly installed and maintained. Failing to obtain or maintain these permits can lead to legal penalties and operational disruptions.

- Zoning and Location Restrictions

Local zoning regulations may restrict where mobile food platforms can operate. These restrictions are often implemented to manage traffic flow, prevent congestion, and protect the interests of brick-and-mortar businesses. Operating in violation of zoning ordinances can result in fines and forced relocation.

- Waste Disposal Protocols

Proper waste disposal is critical for maintaining hygiene and preventing environmental contamination. Regulatory compliance mandates adherence to specific waste disposal protocols, including the proper handling of food scraps, grease, and other waste materials. Failure to comply can lead to fines and damage to the operator’s reputation.

The multifaceted nature of regulatory compliance underscores its importance in ensuring the sustainability and legitimacy of mobile food platforms. Navigating this complex landscape requires careful planning, diligent record-keeping, and a commitment to upholding the highest standards of safety and hygiene. Successfully meeting these regulatory requirements not only safeguards public health but also enhances the credibility and trustworthiness of the entire system.

2. Temperature Integrity

Temperature integrity represents a critical, non-negotiable aspect of mobile food distribution. The capacity to maintain comestibles within specified temperature ranges throughout the transportation process directly influences food safety and palatability. Failure to adhere to established temperature guidelines can foster microbial growth, rendering food unsafe for consumption and potentially leading to foodborne illnesses. The cause-and-effect relationship is direct: inadequate temperature control results in compromised food quality and heightened health risks. For example, delivering chilled salads above 40F (4.4C) for extended periods creates an environment conducive to bacterial proliferation, impacting consumer well-being.

Practical implementations of maintaining temperature integrity encompass several layers. Insulated containers, equipped with phase-change materials or active refrigeration units, constitute the primary defense against temperature fluctuations. Real-time temperature monitoring systems, integrated with GPS tracking, allow operators to proactively address deviations from optimal conditions. Furthermore, stringent protocols for loading, unloading, and handling food items minimize exposure to ambient temperatures. Consider the delivery of prepared sushi; deviations as small as 5 degrees above the required temperature could cause quality and safety concerns.

In summary, temperature integrity is not merely a regulatory requirement but a fundamental principle underpinning responsible mobile food distribution. Challenges remain, including mitigating temperature variations during peak service hours and developing cost-effective, environmentally sustainable cooling solutions. However, prioritizing temperature integrity remains paramount, ensuring consumer safety, reducing food waste, and fostering trust in the evolving landscape of mobile food services.

3. Route Efficiency

Route efficiency constitutes a foundational element in the effective operation of mobile food distribution platforms. Optimized routing directly impacts operational costs, delivery times, and the overall viability of such services. Careful consideration of various factors is essential to maximize route efficiency.

- Distance Minimization

The primary objective of route optimization is to minimize the total distance traveled by the platform. Shorter routes directly translate into reduced fuel consumption, lower vehicle wear and tear, and decreased labor costs. Algorithms and software solutions are frequently employed to identify the most direct paths between delivery points, considering factors such as traffic patterns and road conditions. An example would involve dynamically adjusting a delivery route to bypass a known construction zone, saving both time and fuel.

- Time Window Management

Many deliveries are subject to specific time constraints or customer preferences. Route optimization must account for these time windows, ensuring that deliveries arrive within the designated periods. This may involve prioritizing certain deliveries based on their urgency or geographical proximity, potentially altering the sequence of stops to accommodate all time-sensitive orders. Failure to meet pre-defined delivery windows could lead to customer dissatisfaction and order cancellations.

- Load Balancing and Capacity Planning

Efficient route planning also requires careful consideration of the platform’s capacity and the volume of orders being transported. Overloading the platform can compromise safety and efficiency, while underutilizing its capacity increases per-delivery costs. Route optimization must strike a balance between maximizing the platform’s load and minimizing travel distance. An example of load balancing would be strategically assigning deliveries to different platforms based on their size and weight, ensuring that each platform is operating near its optimal capacity.

- Dynamic Rerouting and Real-time Adjustments

Unforeseen circumstances, such as traffic accidents, road closures, or sudden increases in demand, can disrupt planned routes. Route optimization systems must be capable of dynamically rerouting platforms in real-time to mitigate the impact of these disruptions. This requires continuous monitoring of traffic conditions, weather patterns, and order volumes, as well as the ability to quickly generate alternative routes that minimize delays. For example, automatically reassigning a delivery to a platform closer to the customer if the original platform encounters a significant traffic delay.

These interwoven facets of route efficiency, when implemented effectively, contribute significantly to the economic viability and operational success of mobile food platforms. Strategic investment in route optimization technology and processes is essential to ensure timely deliveries, minimize costs, and maintain a competitive edge in the rapidly evolving landscape of mobile food distribution.

4. Platform Maintenance

Effective operation of any mobile food delivery system hinges critically on consistent and thorough platform maintenance. This proactive approach ensures not only the longevity and reliability of the delivery vehicles but also directly contributes to food safety and operational efficiency. Neglecting platform maintenance can lead to equipment failures, delays, and potential health hazards, jeopardizing the entire food distribution process.

- Mechanical Integrity and Vehicle Safety

Regular inspections and maintenance of vehicle components, such as brakes, tires, suspension, and steering systems, are essential for ensuring safe operation. A vehicle malfunction during transit can lead to delivery delays, food spoilage, and even accidents. Scheduled maintenance mitigates these risks, ensuring that the delivery platform remains roadworthy and capable of executing its intended function without compromising safety. For instance, neglecting tire maintenance can result in blowouts, causing delays and potentially impacting the temperature integrity of perishable goods.

- Temperature Control System Maintenance

For platforms transporting temperature-sensitive food items, maintaining the integrity of refrigeration or heating units is crucial. Malfunctioning temperature control systems can render food unsafe for consumption, leading to potential health risks and regulatory violations. Regular servicing of these systems, including cleaning, calibration, and component replacement, ensures that the platform can consistently maintain the required temperature ranges. Consider the impact of a refrigeration unit failure on a platform transporting sushi; prompt maintenance is essential to prevent spoilage and potential health hazards.

- Hygiene and Sanitation Protocols

Regular cleaning and sanitation of the platform’s interior are vital for preventing the spread of foodborne illnesses. Surfaces that come into contact with food items must be disinfected regularly to eliminate bacteria and other pathogens. Establishing and adhering to strict hygiene protocols protects consumer health and maintains the platform’s compliance with food safety regulations. For example, regularly sanitizing the interior of a delivery vehicle after transporting raw meat minimizes the risk of cross-contamination.

- Power and Electrical Systems

For platforms utilizing electric vehicles or onboard electrical equipment, maintaining the power and electrical systems is essential for uninterrupted operation. Regular inspections and maintenance of batteries, wiring, and charging systems prevent breakdowns and ensure that the platform can complete its deliveries without power-related issues. A failing battery in an electric delivery vehicle can cause significant delays, disrupting the entire delivery schedule and potentially impacting food quality.

These multifaceted aspects of platform maintenance directly influence the reliability, safety, and efficiency of food delivery systems. By prioritizing proactive maintenance strategies, operators can minimize the risk of equipment failures, maintain food safety standards, and ensure the long-term viability of their mobile food distribution operations.

5. Secure Packaging

Secure packaging constitutes an indispensable element in the successful implementation of mobile food delivery platforms. It addresses not only the preservation of food quality and temperature but also the prevention of contamination and spillage during transit. The integrity of the packaging directly influences customer satisfaction and perceptions of food safety.

- Protection Against Physical Damage

Packaging must be designed to withstand the rigors of transportation, including bumps, vibrations, and sudden stops. Durable materials and robust construction are necessary to prevent crushing, tearing, or other forms of physical damage that could compromise the food’s integrity. For example, using rigid containers for delicate pastries ensures they arrive intact and presentable.

- Thermal Insulation Properties

Packaging plays a crucial role in maintaining the desired temperature of food items during delivery. Insulated containers, utilizing materials such as expanded polystyrene or foil-lined bags, minimize heat transfer and help to keep hot food hot and cold food cold. This is particularly important for perishable items, where temperature fluctuations can lead to spoilage. The transport of ice cream, for example, relies heavily on effective insulation to prevent melting.

- Prevention of Spillage and Leakage

Leak-proof and spill-resistant packaging is essential to prevent messes and ensure that food arrives in a presentable condition. Secure closures and tight seals are necessary to contain liquids and prevent them from leaking during transit. This aspect of secure packaging is particularly important for soups, sauces, and other liquid-based dishes. The use of tamper-evident seals can also enhance customer confidence in the hygiene of the delivered product.

- Compliance with Food Safety Regulations

Packaging materials must comply with all applicable food safety regulations, ensuring that they are non-toxic and do not leach harmful chemicals into the food. Proper labeling, including information about ingredients, allergens, and storage instructions, is also a critical aspect of compliance. Using food-grade materials and adhering to labeling requirements ensures that the packaging does not compromise the safety or integrity of the food being delivered.

The integration of these elements of secure packaging directly impacts the reliability and consumer confidence in mobile food delivery services. Investment in appropriate packaging solutions minimizes the risk of damage, spoilage, and contamination, ultimately contributing to a positive customer experience and the sustained success of the food delivery system.

6. Personnel Training

Effective operation of mobile food distribution platforms necessitates comprehensive personnel training. The proficiency of staff directly impacts food safety, customer service, and adherence to regulatory standards, thus affecting the overall success of the operation. Proper training mitigates risks and enhances the efficiency of the delivery process.

- Food Safety Handling Protocols

Personnel training must encompass thorough instruction on food safety handling protocols. This includes proper handwashing techniques, temperature monitoring procedures, and cross-contamination prevention. Delivery personnel are the last point of contact with the food before it reaches the consumer; therefore, their adherence to these protocols is crucial in preventing foodborne illnesses. An improperly trained employee could unknowingly contaminate food, leading to adverse health consequences and reputational damage for the business.

- Safe Driving Practices and Vehicle Operation

Training programs must emphasize safe driving practices and proper vehicle operation. Delivery personnel must be proficient in navigating urban environments, adhering to traffic laws, and handling the delivery platform safely. This includes instruction on defensive driving techniques, hazard awareness, and emergency procedures. Insufficient training in these areas can lead to accidents, injuries, and property damage, potentially disrupting the delivery schedule and incurring significant costs.

- Customer Service and Communication Skills

Personnel training should include instruction on customer service and effective communication skills. Delivery personnel represent the company and are often the primary point of contact for customers. They must be able to communicate clearly, address customer inquiries effectively, and resolve any issues that may arise during the delivery process. Poor communication skills can lead to misunderstandings, dissatisfaction, and negative reviews, impacting customer loyalty and brand reputation. Training on conflict resolution and de-escalation techniques is also valuable.

- Emergency Response Procedures

Training programs must incorporate emergency response procedures, including protocols for handling accidents, injuries, and food safety incidents. Personnel must be trained to respond quickly and effectively to emergencies, ensuring the safety of themselves, customers, and the public. This includes instruction on first aid, CPR, and emergency contact procedures. A well-trained employee can mitigate the impact of an emergency situation, minimizing potential harm and preventing further complications.

In conclusion, personnel training is not merely an operational consideration but a fundamental investment in the safety, efficiency, and success of mobile food distribution platforms. Thorough and ongoing training programs equip personnel with the knowledge and skills necessary to perform their duties effectively, contributing to a positive customer experience and the long-term sustainability of the business. Continuous assessment and updates to the training curriculum are crucial to adapt to evolving regulations and best practices within the industry.

Frequently Asked Questions Regarding Mobile Food Platforms

This section addresses common inquiries and misconceptions concerning the deployment and operation of mobile food distribution platforms.

Question 1: What constitutes a “mobile food platform”?

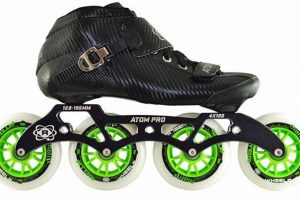

A mobile food platform refers to any motorized or non-motorized conveyance designed for the transportation and delivery of food products. This may encompass modified bicycles, electric scooters, or purpose-built vehicles equipped for temperature-controlled transport.

Question 2: What are the primary regulatory hurdles facing mobile food platform operators?

Operators encounter a range of regulatory challenges, including compliance with food safety standards, zoning restrictions, vehicle permitting requirements, and waste disposal protocols. Adherence to these regulations is mandatory for legal operation.

Question 3: How is temperature integrity maintained during food transport via mobile platforms?

Temperature integrity relies on a multi-faceted approach involving insulated containers, active refrigeration systems, and real-time temperature monitoring. Adherence to established temperature guidelines is critical for preventing foodborne illnesses.

Question 4: What role does route optimization play in the efficiency of mobile food platforms?

Route optimization minimizes travel distance, fuel consumption, and delivery times. Sophisticated algorithms and real-time traffic data are employed to identify the most efficient routes, accounting for time constraints and unforeseen disruptions.

Question 5: What measures are taken to ensure the safety and security of food products during transit?

Secure packaging, including tamper-evident seals and durable containers, is utilized to prevent spillage, contamination, and physical damage. These measures contribute to maintaining food quality and building consumer trust.

Question 6: What training is provided to personnel operating mobile food platforms?

Personnel receive comprehensive training in food safety handling, safe driving practices, customer service skills, and emergency response procedures. This training ensures that personnel are equipped to handle various situations effectively and maintain the highest standards of service.

Key takeaways emphasize the importance of regulatory compliance, temperature control, route optimization, secure packaging, and comprehensive personnel training in ensuring the safe and efficient operation of mobile food platforms.

The following section will explore the future trends and potential societal impact of this evolving mode of food distribution.

Concluding Remarks on Food Skate Systems

This exploration has elucidated the critical elements underpinning the viability and safety of food skate systems. Strict regulatory adherence, meticulous temperature maintenance, optimized routing strategies, robust platform maintenance, secure packaging solutions, and comprehensive personnel training constitute essential pillars for successful operation. Neglecting any of these facets introduces significant risks to public health, operational efficiency, and long-term sustainability.

Continued innovation and diligent oversight are imperative to ensure that food skate systems evolve responsibly. The effective integration of technology, coupled with a steadfast commitment to safety and ethical practices, will determine the extent to which these systems can contribute to a more accessible and sustainable food distribution network. Further research and investment are warranted to refine operational protocols and mitigate potential challenges as this sector continues to develop.