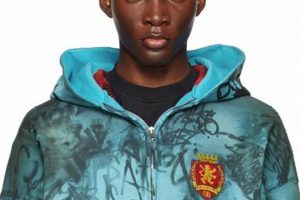

Garments displaying the branding of a prominent skateboarding company based in Santa Cruz, California, are commonly worn by skateboarders and those interested in skate culture. These articles of clothing often feature the company’s iconic logos and graphic designs, serving as a recognizable symbol within the skateboarding community and beyond. An example would be a short-sleeved crew neck top, typically constructed of cotton or a cotton blend, displaying the “Screaming Hand” logo.

The popularity of apparel from this company stems from its long-standing presence and influence in the skateboarding industry. Wearing items with the brands imagery can signify an affiliation with the skate lifestyle and appreciation for its history. These items provide a tangible connection to a brand recognized for its contribution to skateboarding culture, offering a sense of belonging and shared identity. Historically, wearing such apparel denoted an authentic engagement with the skateboarding scene.

The subsequent sections will delve into aspects such as the evolution of designs, the impact on fashion trends, and the availability of diverse styles within the brand’s clothing line. It will further explore the materials used, the manufacturing processes involved, and the overall consumer appeal of the company’s offerings.

Selection and Care Recommendations

The following recommendations offer guidance on the acquisition and maintenance of garments bearing the logos of the Santa Cruz Skateboards brand, aiming to maximize longevity and satisfaction.

Tip 1: Authenticate Purchase Source: Prioritize purchasing from authorized retailers or the official company website. This minimizes the risk of acquiring counterfeit items, which may exhibit inferior quality and deviate from the brand’s intended design.

Tip 2: Assess Fabric Composition: Scrutinize the fabric composition listed on the garment’s label. Opt for higher quality cotton blends or performance fabrics designed for durability and comfort during physical activity. Consider the intended use when selecting the appropriate material.

Tip 3: Examine Print Quality: Closely inspect the quality of the printed graphic or logo. A well-executed print will exhibit vibrant colors, sharp lines, and resistance to cracking or fading after repeated washing. Avoid items with visible imperfections in the print.

Tip 4: Observe Stitching Integrity: Evaluate the stitching along seams, hems, and other critical areas. Secure and even stitching indicates a well-constructed garment that is less prone to tearing or unraveling during wear and washing. Reinforcements at stress points are desirable.

Tip 5: Follow Washing Instructions: Adhere strictly to the washing instructions provided on the garment’s care label. Washing inside out, using cold water, and avoiding harsh detergents can help preserve the color and print quality. Tumble drying on low heat or air drying is recommended.

Tip 6: Implement Proper Storage: Store garments folded or hung in a dry, cool environment to prevent mildew or discoloration. Avoid prolonged exposure to direct sunlight, which can cause fading of colors and degradation of the fabric.

Tip 7: Address Stains Promptly: Treat stains as quickly as possible to prevent them from setting. Use appropriate stain removal products or techniques based on the type of stain and the fabric composition. Avoid using excessive force or harsh chemicals that can damage the fabric or print.

Adherence to these recommendations should contribute to a prolonged lifespan and sustained visual appeal of the apparel. By prioritizing quality, proper care, and informed selection, one can ensure lasting enjoyment of these iconic pieces of skate culture.

The subsequent sections will focus on the cultural significance of the Santa Cruz Skateboards brand within the broader context of skateboarding history and its ongoing influence on contemporary fashion trends.

1. Iconic Graphic Designs

The enduring appeal and market presence of apparel associated with Santa Cruz Skateboards are inextricably linked to its graphic designs. These images, often bold and instantly recognizable, transcend mere decoration, serving as powerful identifiers within the skateboarding subculture and symbols of the brand itself.

- The Screaming Hand

The “Screaming Hand,” designed by Jim Phillips Sr., represents one of the most universally recognized symbols in skateboarding. Its recurring presence on garments bearing the brand’s name signifies not only brand allegiance but also membership within a global community of skateboarders and enthusiasts. The design’s visceral imagery contributes to the shirt’s immediate recognition and appeal.

- Classic Logo Variations

Beyond the “Screaming Hand,” various iterations of the brand’s wordmark and other graphic elements contribute to the distinctive character of the shirts. These range from simple, block-letter logos to more elaborate designs incorporating skulls, flames, or other motifs commonly associated with skate culture. The consistent application of these designs across a range of apparel reinforces brand identity and recognition.

- Collaboration and Artist Series

Santa Cruz Skateboards has a history of collaborating with artists to create limited-edition graphic designs. This approach introduces fresh perspectives and aesthetic styles while maintaining a connection to the core skateboarding demographic. These collaborations enhance the collectability and value of the shirts, attracting both dedicated fans and art enthusiasts.

- Evolution and Adaptation

While retaining the essence of its iconic designs, the brand periodically updates and adapts its graphics to reflect contemporary trends and appeal to evolving consumer preferences. This adaptability ensures that the shirts remain relevant and desirable without sacrificing the brand’s established visual identity. Subtile alterations in color palettes, print techniques, and graphic placement demonstrate this strategic evolution.

In conclusion, the incorporation of these iconic graphic designs is a critical factor in the ongoing success and cultural relevance of attire associated with Santa Cruz Skateboards. The graphics serve as both a marketing tool and a visual language that resonates with the skateboarding community and beyond, underscoring the power of design in shaping brand identity and consumer appeal.

2. Brand Recognition

The enduring visibility and commercial success of apparel prominently featuring the Santa Cruz Skateboards logo are intrinsically linked to its high level of brand recognition. This recognition, built over decades, transcends mere awareness; it represents a deep-seated association with skateboarding culture, innovation in board design, and a legacy of iconic graphics. The presence of the company’s visual identifiers on the shirts acts as a shorthand, instantly conveying these associations to both participants and observers of the skateboarding world. The causal relationship is evident: the strength of the brand’s image directly fuels the demand for its associated merchandise. For example, the widespread visibility of the “Screaming Hand” logo on these shirts, both in media and in public spaces, reinforces the brand’s prominence and desirability.

The importance of brand recognition as a component of apparel associated with Santa Cruz Skateboards is multifaceted. First, it provides a sense of belonging and identity for wearers who identify with skateboarding culture. The shirt becomes a visible declaration of this affiliation. Second, the established reputation and image translate into a perceived assurance of quality and authenticity. Consumers may be more inclined to purchase these shirts, believing they are investing in a product backed by a reputable and established brand. This is particularly true in a market saturated with generic alternatives. Finally, strong brand recognition enables the company to command a premium price point, reflecting the added value attributed to the name and its associated imagery. This can be seen in the price comparisons between a graphic tee from the Santa Cruz brand versus similar tees from less recognizable brands.

In summary, the nexus between brand recognition and the popularity of these shirts is a prime example of how a company’s history and consistent branding efforts can create tangible market value. The challenge for the brand lies in maintaining its authenticity and relevance as trends evolve, ensuring that its established image continues to resonate with both core skateboarding enthusiasts and a broader consumer base. The long-term success of the apparel line depends on preserving the integrity and cultural significance that underpin its high level of brand recognition.

3. Material quality

The perceived value and long-term usability of apparel associated with Santa Cruz Skateboards are fundamentally linked to the quality of materials utilized in their construction. Inferior materials can result in diminished comfort, reduced durability, and a decline in the overall aesthetic appeal of the garment, thereby negatively impacting brand perception. The selection of appropriate fabrics and components, therefore, represents a critical factor influencing consumer satisfaction and product longevity. For instance, a shirt constructed from low-grade cotton may exhibit significant shrinkage after washing, fading of printed graphics, and a propensity for tearing, whereas a garment employing higher-quality materials would demonstrate greater resistance to these issues.

The choice of materials directly affects the garment’s suitability for the activities typically associated with the skateboarding lifestyle. Shirts subjected to the rigors of skateboarding require fabrics capable of withstanding abrasion, stretching, and frequent washing. The incorporation of materials such as durable cotton blends, moisture-wicking synthetics, or reinforced stitching at stress points contributes to enhanced performance and resilience. As an example, consider the difference in wear between a basic t-shirt and one marketed for skateboarding use. The latter is likely to be made of a heavier, more durable material and have reinforced seams to withstand the physical demands of the sport.

In conclusion, material quality is an indispensable component of garments bearing the Santa Cruz Skateboards branding. It directly influences the perceived value, durability, and suitability of the product for its intended use. While aesthetic design and brand recognition contribute to initial purchasing decisions, the long-term satisfaction and repeat business are dependent on the tangible attributes of the materials utilized. Consequently, maintaining a commitment to quality materials is essential for sustaining the brand’s reputation and ensuring the continued demand for its apparel offerings.

4. Target Demographic

The success and continued market relevance of apparel emblazoned with Santa Cruz Skateboards branding are inextricably linked to a clearly defined target demographic. Understanding and effectively reaching this audience are crucial for maintaining brand loyalty and driving sales within a competitive market.

- Core Skateboarders

The primary target demographic consists of individuals actively engaged in skateboarding. These consumers view the brand not merely as a clothing provider, but as an integral part of their lifestyle. The shirts serve as a visible symbol of their affiliation with skateboarding culture. Purchase decisions are often driven by a desire to support the brand’s legacy and identify with its associated values. For example, a skateboarder might specifically seek out a shirt featuring a classic deck graphic as a nod to the brand’s history.

- Skate Culture Enthusiasts

Extending beyond active participants, the target demographic includes individuals who appreciate skateboarding culture without necessarily engaging in the activity itself. These enthusiasts may be drawn to the aesthetic, the music, or the overall counter-cultural image associated with the sport. The shirts function as a way to express their affinity for this subculture and align themselves with its values. An example might be a music fan drawn to the punk rock bands often associated with the skateboarding scene, adopting the associated clothing as a symbol of that alignment.

- Youth and Young Adults

A significant portion of the target demographic comprises younger individuals, particularly teenagers and young adults. These consumers are often influenced by current trends and gravitate towards brands perceived as cool or authentic. Apparel offers a relatively accessible entry point into the brand, allowing them to express their individuality and signal their affiliation with a desired social group. The visibility of the shirts on social media and in popular culture further reinforces their appeal to this demographic.

- Collectors and Nostalgia Seekers

A niche segment of the target demographic consists of individuals who collect vintage or limited-edition items associated with the brand. These consumers are often motivated by nostalgia, a desire to preserve skateboarding history, or an appreciation for unique designs. The shirts, particularly those featuring rare or discontinued graphics, can become highly sought-after collector’s items. An example is the market for vintage “Screaming Hand” shirts from the 1980s and 1990s.

Ultimately, the effectiveness of marketing and design efforts directed toward apparel linked to Santa Cruz Skateboards hinges on a thorough understanding of these target demographics. By tailoring products, messaging, and distribution strategies to resonate with the specific needs and preferences of each segment, the brand can maximize its reach and maintain its position within a dynamic and competitive marketplace.

5. Cultural Relevance

The enduring market presence of garments bearing the Santa Cruz Skateboards branding is inextricably linked to their continued cultural relevance within the skateboarding community and beyond. This relevance transcends mere fashion; it represents an affiliation with a history of innovation, a specific aesthetic, and a set of values associated with the skateboarding lifestyle. The shirts function as wearable symbols, communicating an individual’s connection to this culture. The effect is that these garments provide an outward signifier of an individual’s participation, appreciation, or endorsement of the skateboarding ethos. The prevalence of such apparel in skateboarding media and public spaces reinforces and perpetuates this connection, solidifying the brand’s position within the cultural landscape.

The importance of cultural relevance as a component of these shirts manifests in several ways. First, the designs often incorporate iconic imagery and historical references that resonate with skateboarders and enthusiasts. The “Screaming Hand” logo, for example, has become synonymous with the brand and with skateboarding culture in general, serving as a visual shorthand recognized across generations. Second, the brand’s association with influential skateboarders and events further solidifies its cultural standing. Sponsorships, collaborations, and participation in skateboarding competitions create a feedback loop, reinforcing the brand’s authenticity and relevance. Consider, for example, the impact of a legendary skateboarder wearing the brand, thereby amplifying its visibility and desirability within the target demographic. This visibility helps create a sense of community among those wearing the brand apparel as well.

In summary, the continued demand for attire with the Santa Cruz Skateboards logo relies heavily on maintaining its cultural relevance. The brand must navigate evolving trends and cultural shifts while remaining true to its skateboarding roots. Failing to do so risks alienating its core audience and diluting the brand’s unique identity. Understanding and nurturing this cultural connection is paramount for the long-term success and sustainability of the apparel line, ensuring it remains more than just clothing but a tangible representation of a vibrant and enduring subculture.

6. Retail availability

The accessibility of garments bearing the Santa Cruz Skateboards logo significantly impacts their overall market performance and brand visibility. Widespread retail availability, encompassing both physical stores and online platforms, directly influences consumer purchasing decisions and the brand’s ability to reach its target demographic. The strategic placement of these shirts in various retail outlets, ranging from specialized skate shops to mainstream clothing retailers, is a critical factor in driving sales and expanding brand awareness. Limited availability can restrict consumer access and potentially diminish brand desirability, while overly broad distribution might dilute the brand’s image and appeal.

The distribution strategy associated with these shirts requires careful consideration of several factors, including the target audience, brand image, and pricing strategy. Exclusive partnerships with select retailers can enhance the perceived value and exclusivity of the products, while broader distribution channels ensure accessibility to a wider consumer base. The rise of e-commerce has further expanded the reach of these shirts, allowing consumers worldwide to purchase them directly from the company’s website or through online retailers. For example, the presence of Santa Cruz Skateboards apparel on major online marketplaces, coupled with its availability in independent skate shops, reflects a multi-faceted approach to retail distribution. This approach increases the likelihood of reaching different consumer segments.

In summary, retail availability serves as a crucial link between the design and production of these shirts and their ultimate consumption by the target audience. A well-defined distribution strategy, encompassing both physical and online channels, is essential for maximizing sales, enhancing brand visibility, and maintaining cultural relevance within the skateboarding community and beyond. Challenges remain in balancing exclusivity with accessibility and adapting to the evolving retail landscape, but a strategic approach to retail availability remains a cornerstone of the brand’s success.

7. Print durability

Print durability represents a critical factor in the overall value and longevity of apparel bearing the Santa Cruz Skateboards logo. The application of graphics, often iconic and central to the brand’s identity, constitutes a significant element of these garments’ appeal. The print’s ability to withstand repeated washing, wear, and exposure to environmental factors directly affects the perceived quality and lifespan of the shirt. Consequently, inadequate print durability can lead to premature degradation of the graphic, resulting in consumer dissatisfaction and a diminished representation of the brand. The relationship between print quality and customer satisfaction is inextricably linked; a shirt where the design fades or cracks quickly detracts from the garment’s overall value and the brand’s reputation.

The selection of appropriate printing methods and materials significantly influences print durability. Techniques such as screen printing, utilizing high-quality inks and curing processes, generally yield more robust and long-lasting prints compared to direct-to-garment (DTG) printing, especially when handling intricate designs or specific fabric types. Furthermore, the pre-treatment of the fabric, the type of ink used (e.g., plastisol vs. water-based), and the curing temperature all contribute to the final print’s resistance to wear and tear. An illustrative example is the contrast between a cheaply produced shirt with a thin, easily cracked print and a higher-quality shirt where the print remains vibrant and intact even after numerous wash cycles. The practical significance lies in the recognition that investing in quality printing techniques results in a product that maintains its aesthetic appeal and value over time, thereby enhancing customer loyalty and repeat purchases. Shirts exhibiting enduring prints reinforce brand quality to prospective consumers.

In summary, print durability is not merely a cosmetic detail but a fundamental component of apparel linked to Santa Cruz Skateboards. It directly impacts consumer satisfaction, brand perception, and the long-term value of the garment. By prioritizing high-quality printing methods and materials, the brand can ensure that its iconic graphics remain vibrant and intact, thereby reinforcing its reputation for quality and commitment to skateboarding culture. The challenge lies in balancing cost-effectiveness with the need for enduring print quality, requiring a strategic approach to production and quality control. The end result is a product that continues to represent the brand positively long after the initial purchase.

Frequently Asked Questions

This section addresses common inquiries regarding apparel displaying the Santa Cruz Skateboards logo, offering clear and concise information on various aspects of these garments.

Question 1: What distinguishes an authentic garment from a counterfeit version?

Authentic items can be identified by several factors. High-quality construction, durable fabric, and precise printing are key indicators. Official merchandise will typically include proper labeling with trademark information and care instructions. Purchasing from authorized retailers or the official website minimizes the risk of acquiring counterfeit products.

Question 2: How can the print on the garment be preserved to maximize longevity?

To prolong the life of the print, it is recommended to wash the garment inside out in cold water. Avoid using harsh detergents or bleach. Tumble drying on low heat or air drying is preferable. Avoid ironing directly over the printed area.

Question 3: What are the most common materials used in the construction of these garments?

The majority of such apparel utilizes cotton or cotton blends. Some garments may incorporate polyester or other synthetic fibers to enhance durability or moisture-wicking properties. The specific material composition is typically indicated on the garment’s label.

Question 4: Are there variations in fit and sizing across different styles and designs?

Variations in fit and sizing can occur due to differences in design and manufacturing processes. It is advisable to consult the size chart provided by the retailer or manufacturer before making a purchase. Customer reviews may also provide insights into the accuracy of sizing.

Question 5: How does the brand ensure ethical and sustainable manufacturing practices?

Information regarding the brand’s commitment to ethical and sustainable manufacturing practices can often be found on their official website or in their corporate social responsibility reports. Certifications from recognized organizations may also indicate adherence to specific environmental or labor standards.

Question 6: Where can one find limited-edition or vintage versions of these garments?

Limited-edition or vintage items may be found at specialized skate shops, online marketplaces specializing in vintage apparel, or through auctions. Authenticity should be carefully verified before purchasing vintage or rare items.

The information provided in these FAQs serves as a general guide. Specific product details and care instructions may vary. Always consult the manufacturer’s information for accurate and up-to-date guidance.

The following sections will focus on related products and apparel and how they contribute to the style.

Concluding Assessment

The preceding analysis has examined various facets of garments bearing the Santa Cruz Skateboards logo, encompassing design elements, brand recognition, material quality, target audience, cultural significance, retail availability, and print durability. These shirts represent more than mere apparel; they function as tangible expressions of affiliation with a specific subculture and a legacy of innovation within the skateboarding industry. Each element discussed contributes to the overall value and market position of these items.

Continued success necessitates an ongoing commitment to quality, authenticity, and a nuanced understanding of the evolving preferences within the skateboarding community. The brand’s ability to adapt to changing trends while upholding its established values will determine its future relevance and market position. Further investigation of consumer behavior and market dynamics is recommended to ensure continued strategic alignment and sustained growth.